Fixing Common Issues with Your Galvanometer Scanner: Tips and Tricks

Fixing Common Issues with Your Galvanometer Scanner: Tips and Tricks

Blog Article

Trick Applications of a Galvanometer Scanner in Various Scientific Research Area

Galvanometer scanners have become essential to numerous clinical research fields, providing improved precision in applications ranging from biomedical imaging to environmental tracking. Their ability to facilitate high-resolution imaging strategies, such as confocal microscopy, plays an important duty beforehand our understanding of mobile frameworks. In addition, in material handling, these tools improve the precision of laser cutting and welding. As we check out the diverse applications of galvanometer scanners, it ends up being obvious that their impact expands much beyond mere technological abilities, increasing concerns concerning their future capacity in arising research locations.

Biomedical Imaging

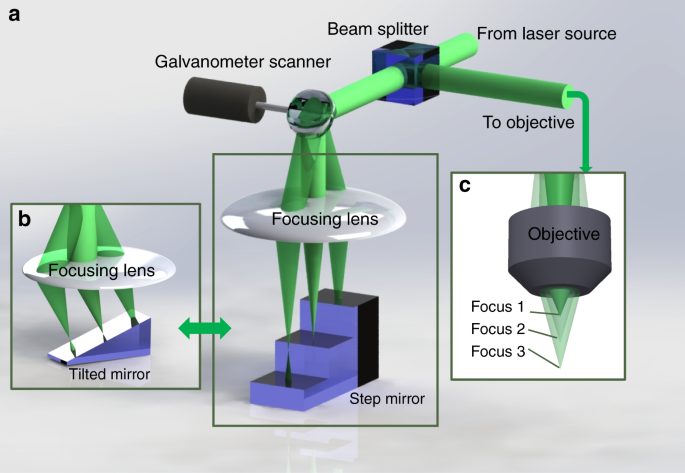

In confocal microscopy, galvanometer scanners facilitate the acquisition of pictures with improved resolution and comparison, permitting researchers to visualize mobile components in vivo. The ability to quickly catch numerous focal airplanes boosts the three-dimensional restoration of cells, giving important insights into their design and function.

Moreover, the rapid scanning capacities of galvanometer systems contribute to developments in dynamic imaging applications, such as checking cellular responses to stimulations. Galvanometer scanners are indispensable devices in the field of biomedical imaging, progressing research and medical diagnostics via their accuracy and efficiency.

Product Handling

Precision in product processing is critical for accomplishing top quality lead to different industrial applications (galvanometer scanner). Galvanometer scanners play a crucial function in boosting this precision by enabling rapid and accurate movement control during the handling of materials such as polymers, ceramics, and metals. These tools promote strategies like laser welding, engraving, and cutting, which require finely-tuned adjustments to ensure ideal end results

In laser cutting, for circumstances, galvanometer scanners permit complex layouts to be implemented with high fidelity, decreasing waste and boosting manufacturing performance. The quick movement capabilities allow fast adjustments in the laser light beam path, which is important for maintaining regular cutting top quality across differing product densities. In laser welding applications, the accuracy supplied by galvanometer scanners makes certain strong joints with marginal thermal distortion, therefore boosting structural integrity.

Moreover, the versatility of galvanometer scanners to various laser types and wavelengths further widens their utility in material processing. Their capability to function in tandem with advanced software for real-time tracking and control includes an additional layer of sophistication, allowing manufacturers to accomplish specific specifications tailored to certain applications. Hence, galvanometer scanners are important in progressing the capacities of product handling modern technologies.

Optical Characterization

In the world of optical characterization, the duty of galvanometer scanners comes to Recommended Site be increasingly considerable as they promote the analysis of various optical homes with high accuracy. These gadgets allow exact control of laser beams, permitting scientists to methodically probe materials at several angles and regularities. This capacity is vital for identifying the refractive index, absorption coefficient, and scattering residential properties of diverse materials.

Galvanometer scanners are especially efficient in methods such as optical comprehensibility tomography (OCT) and laser-induced fluorescence (LIF), where fast scanning is essential. By attaining high-speed modulation of the laser position, galvanometer scanners improve the temporal resolution of these methods, bring about boosted imaging and analysis. Furthermore, they allow the expedition of complex communications in between light and issue, which is important for comprehending material habits under numerous problems.

Furthermore, the assimilation of galvanometer scanners with spectroscopic techniques expands their energy, permitting thorough spooky analysis across a wide variety of wavelengths. This convenience makes them indispensable devices in areas such as products science, biomedical study, and nanotechnology, where thorough optical characterization is critical for advancing understanding and development.

Laser Micromachining

The introduction of laser micromachining has actually transformed manufacturing processes, enabling the development of intricate frameworks with unequaled accuracy. This technique utilizes high-intensity laser light beams to exactly eliminate material from a substratum, making it feasible to make micro-scale elements that are crucial in various markets. The application of galvanometer scanners in laser micromachining enhances the effectiveness and precision of this procedure by enabling accurate and quick beam of light positioning.

Galvanometer scanners assist in the vibrant control of laser light beams, enabling complex patterns to be etched or cut with high fidelity. Their rapid action times and high-resolution capacities permit for the adjustment of laser pulses, which is important for achieving the wanted material homes and surface area finishes. This innovation is particularly beneficial in markets such as electronic devices, where the miniaturization of components is vital for efficiency enhancement.

Furthermore, laser micromachining is significantly being utilized in the medical area for manufacturing precision tools and implants. The combination of laser modern technology and galvanometer scanning not only streamlines production operations however additionally lowers waste and improves general product usage, making it a sustainable choice for contemporary manufacturing difficulties.

Ecological Surveillance

Environmental tracking has come to be progressively essential in managing the health and evaluating of ecosystems and urban settings. The assimilation of find out here now galvanometer scanners in this area makes it possible for precise, quick, and effective data collection, promoting much better decision-making processes. These scanners are experienced at guiding laser beams or sensing units across numerous surfaces, permitting high-resolution mapping of ecological criteria such as air top quality, soil composition, and water air pollution.

In air quality tracking, galvanometer scanners can be utilized to assess particle matter and aeriform contaminants, supplying real-time information that informs public health initiatives. For water high quality assessments, these scanners can assist in finding impurities and determining physical specifications, consequently making sure compliance with environmental laws. In remote noticing applications, galvanometer scanners enhance the capacity of satellite and drone systems to capture in-depth photos and data of substantial locations, recognizing eco-friendly modifications and anthropogenic impacts.

The convenience and accuracy of galvanometer scanners make them important tools in ecological surveillance, adding substantially to lasting advancement efforts and the defense of natural deposits. As the requirement for reliable environmental administration grows, the duty of these innovative devices will most certainly expand better.

Verdict

In summary, galvanometer scanners serve as necessary tools across numerous clinical research study domain names. The versatility and efficiency of galvanometer scanners continue to drive advancements in these critical areas.

In laser welding applications, the precision used by galvanometer scanners ensures solid joints with minimal thermal distortion, thereby improving structural stability.

Furthermore, a fantastic read the flexibility of galvanometer scanners to various laser types and wavelengths further widens their utility in product processing. By accomplishing high-speed inflection of the laser position, galvanometer scanners boost the temporal resolution of these approaches, leading to enhanced imaging and evaluation. The application of galvanometer scanners in laser micromachining enhances the effectiveness and precision of this process by allowing rapid and accurate beam positioning.

Galvanometer scanners promote the vibrant control of laser light beams, making it possible for complicated patterns to be etched or cut with high integrity.

Report this page